NEW POLYETHYLENE SERVICE LINE SQUEEZE OFF TOOL

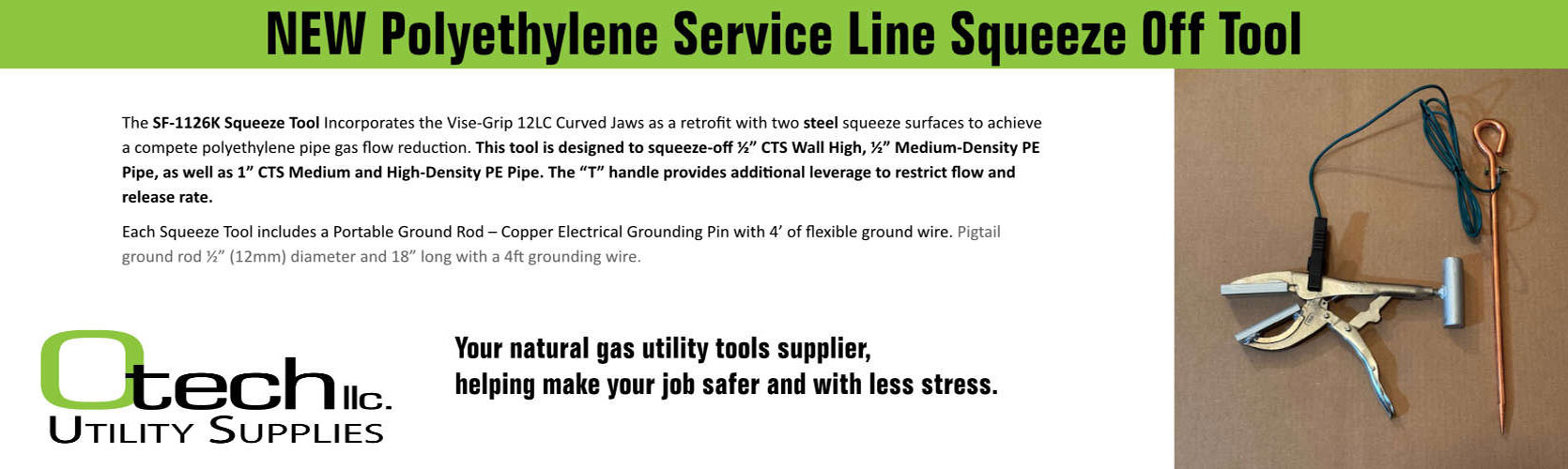

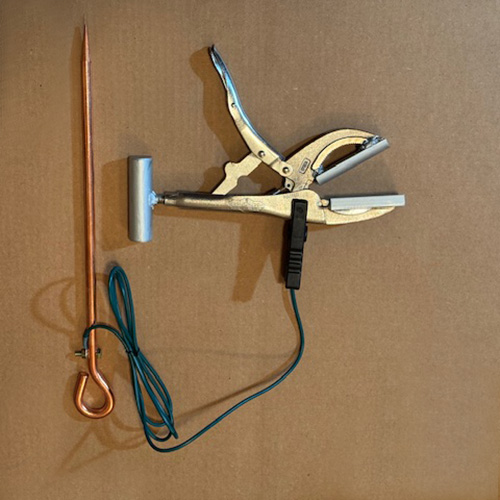

The SF-1126K Squeeze Tool Incorporates the Vise-Grip 12LC Curved Jaws as a retrofit with two steel squeeze surfaces to achieve a complete polyethylene pipe gas flow reduction. This tool is designed to squeeze-off ½” CTS Wall High, ½” Medium-Density PE Pipe, as well as 1” CTS Medium and High-Density PE Pipe. The “T” handle provides additional leverage to restrict flow and release rate.

- ½" CTS .062 Wall High Density PE Pipe

- ½" CTS .090 Wall Medium Density PE Pipe

- 1" CTS .090 & .099 Medium Density Pipe

This tool has been tested by GTI and meets the requirements of ASTM D2513 for sustained pressure on a pipe after the squeeze tool has been applied.

Benefits

- Common Jaw attachments on the SF-1125K Squeeze Off Tool

- Fixed gap squeeze setting ensures the gas line is completely closed off and the pipe is not permanently damaged

- Flat steel surfaces with 90 degree edges provide superior flow control characteristics

- "T" handle provides additional leverage to restrict flow and release rate

- Our 18" 1/2" steel, copper-clad grounding rod is INCLUDED with our squeeze off tool

GROUNDING ROD ATTACHMENT

Polyethylene plastic used in manufacturing gas pipe has many advantages over steel and other materials. However, one disadvantage is the potentially dangerous buildup caused by gas flowing through this non-conductive material. The possibility of static electric discharge during squeeze-off of PE gas pipe is now recognized and addressed by gas utilities and pipe manufacturers. During the normal flow of natural gas in PE pipe, electric charges move in the direction of the gas. When squeeze-off occurs, turbulence and gas velocity increase at the squeeze point, which causes the charges to become heavily concentrated at that same point. As the charge increases in density on the inside wall surface, the force between the charges inside the pipe and the opposing charges outside the pipe increase. When the force exceeds the dielectric strength of the pipe, the charges move through the pipe and creates a pin hole opening in the pipe wall. If the squeeze tool is properly grounded, the discharge will move through the squeeze tool to earth.This phenomenon is aggravated by:

- Sufficient gas flow to cause extensive turbulence, such as the reduced area of pipe during squeeze-off.

- Rust or foreign particles present in the gas.

Regulations and Guidelines

The regulations for squeezing off plastic pipe involves a series of safety and operational guidelines to ensure the integrity of the piping system and the safety of personnel. Be sure to follow your companies’ standards and procedures.- Personal Protective Equipment (PPE): Always wear appropriate PPE, including hard hats safety glasses, safety toe footwear, and appropriately rated traffic vest. In gaseous environments, flame-resistant (FR) PPE is required.

- Safety Precautions: Grounding procedures must be in place to reduce static electricity. Inspect the squeeze-off tool and the pipe for cuts, scrapes, gouges, or anomalies before performing the squeeze-off.

- Tool and Pipe Inspection: Ensure the squeeze-off tool is the proper size, functioning properly, and adjusted for the squeeze-off to be performed. Inspect the pipe for cuts, scrapes, gouges, or anomalies before placing the squeeze-off tool.

- Compressing the Pipe: Compress the pipe at a maximum rate of squeeze-off based on its IPM. If the temperature is below freezing, decrease the maximum rate of squeeze-off to a lower IMP.

- Flow Control: Squeeze the pipe until the flow of gas ceases or the mechanical stops built into the tool are contacted, whichever comes first. Continue the squeeze off procedure beyond this point could damage the pipe or equipment.

- Release the Pipe: Release the pipe at a maximum release rate of IPM. If the temperature is below freezing, decrease the maximum release rate of IPM.

- Inspect the Pipe: After the squeeze-off, inspect the pipe for any signs of damage. The pipe may be re-rounded by rotating the squeeze-off tool 90 degrees and applying enough force to round the pipe or by using a special tool designed for this purpose.

Our products are proudly "Made in Michigan".

GUARANTEE

The GUARANTEE covers material, workmanship and design of products manufactured by Otech llc., and does not guarantee the products of other manufacturers. Otech llc. guarantees the product for three years with use in proper conditions, proper use of product(s) and proper training in use of the product(s). If a product is defective, the product must be returned, freight prepaid, to the factory with complete information regarding the failure of that product. Claims will be disallowed if abuse, modification of the product or lack of proof of purchase is evident. Otech llc., reserves the right to repair or replace subject product(s) and will return to purchaser. Otech llc., reserves the right to change or improve its product without notification or without incurring any liability or obligation to previous products. Otech llc., is not responsible for training in the use of the product(s), injury or damage as a result of misuse, tampering or the lack of training in regards to the use of the product(s) manufactured by Otech llc.Claims or Inquiries should be directed to: Otech llc., PO Box 906, Bloomfield Hills, MI 48303-0906

Email: Contact Us